Composite materials have many potential uses. Here are a few of them to get your creative juices flowing:

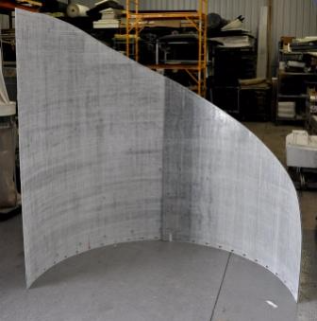

Wind Turbine Blades

Low-pressure Differential Pressure Molding is used to form thermoplastic sandwich panel composite sails for wind turbine blades

Benefits:

- Faster, More Efficient, & Lower Cost Production Process

- Mass Reduction Opportunities for Use on Light Roofs

- Better Able to Meet Increasing Demand for Wind Energy

There are numerous other current and future composites applications in wind-energy, a major area of growth for the entire composites industry

Composite Rebar

An exciting new composites application is the use of fiber-reinforced thermoplastic tapes to pultrude composite rebar that is lighter, more ductile, and impervious to rust vs. conventional epoxy-coated steel

Benefits:

- More Corrosion Resistant, No Concrete Spalling, Much Longer Use Life

- Density About Same as Concrete, so will Stay Where Positioned

- Lower Mass Facilitates Installation & Reduces Structural Loads on Bridge Decking & Parking Decks

- Option to Produce in Continuous Coil to Reduce Installation Time & Costs

Composite Pipe

Elevated pipeline used to convey petroleum is an excellent area for composites owing to their weather, rust, and chemical resistance, and greater

ductility, which can help reduce the risk of leakage

Benefits:

- Pipe: Lighter, Less Expensive, Easier Assembly

- Culvert: Stronger, More Durable, Lower Cost, & Lighter Weight for Easier Installation

- Will not Corrode Like Metal or Spall Like Concrete

- Option to Produce in Continuous Coil to Reduce Joints

- Option to Make Composite Pipe Conductive

Pipe is an active area of research for composite technologies

Other Applications

Transportation

- High impact/stiffness thermoplastic composite beams

- Load floor panels for pass cars, trucks, trailers, and commercial transportation

- Structural composite “springs” and other chassis/hardware applications

- Body-in-White structures

Material Handling

- Pallets

- Dunnage

- Durable shipping crates

Building and Construction

- Interior walls

- Exterior walls

- Ceilings

- Concrete forming panels

There are numerous other current and future composites applications in these markets and many others, providing a major area of growth for the entire composites industry